WE SHAPE OUR CUSTOMERS FUTURE ACHIEVEMENT

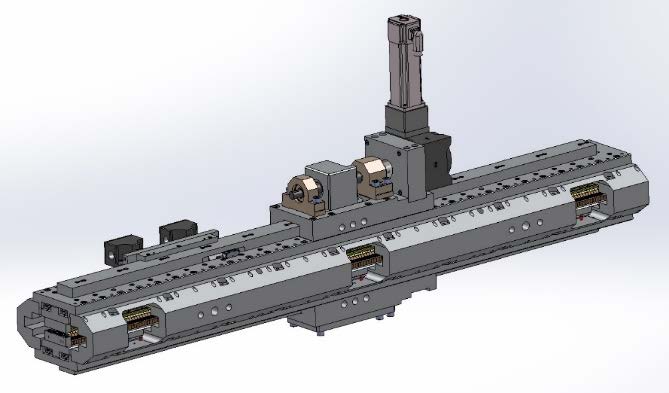

Thanks to the high level of competence in mechanical design and to our ability to produce and assemble high-precision mechanics, we have also provided our clients with the mechanical support structures for the various subsystems of the devices.

The ability to design, realize, and commission control systems is a crucial asset of Kyma. The solid base, on which we develop the software for our devices, efficiently supports our customers while integrating different hardware and software components into a unified control solution.

SKILLS AND TECHNICAL ASSETS

Research and Development are in our DNA.

Kyma is equipped with state-of-the-art systems and apparatuses for magnetic measurement, as well as all the instruments needed to create the complex devices for the accelerator industry. A 220 m2 temperature-controlled chamber in which all the vital magnetic measurement and assembly operations take place, is located inside our laboratory.

Additionally, a cleanroom has been installed in the laboratory. Inside this chamber, the special ventilation and filtration systems keep the air particles at ISO 6 level, which makes it the perfect place for in-vacuum operations.

OUR COSTUMERS

Our products are constantly developing

It is a revolutionary new design that is being adopted more and more frequently by the industry.

We also built more than 60 Phase Shifters for the EuXFEL project in Germany.

Phase Shifters – EuXFEL in Germany

SP-LPU @ SPARC – ENEA Research Centre

PPM Compact Undulators Magnets – Cornell University

Since 2014 Kyma built nine CHESS Compact Undulator (CCU) magnets which are currently installed and successfully operating at the Cornell Electron Storage Ring. CCU magnets are compact, lightweight, economical and vacuum compatible. They are linearly polarized undulators and have a fixed gap. The optimization of the magnetic field is achieved by phasing (moving) the upper magnetic array. Particular attention was given to the soldering technique used for fixing the magnetic blocks to the supports. The evaluation included tests of different types of solder paste, measurements of the binding strength and determination of the deformations of the soldered magnet and the support under simulated external load.

In 2015 Kyma and Cornell University signed a licensing agreement for the construction of PPM Compact undulator magnets.

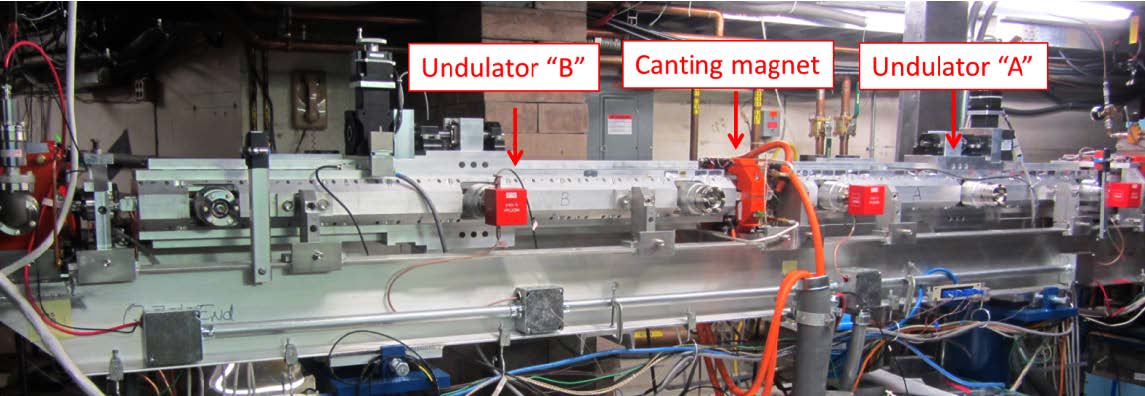

EPUs @ NSLS-II – Brookhaven National Lab

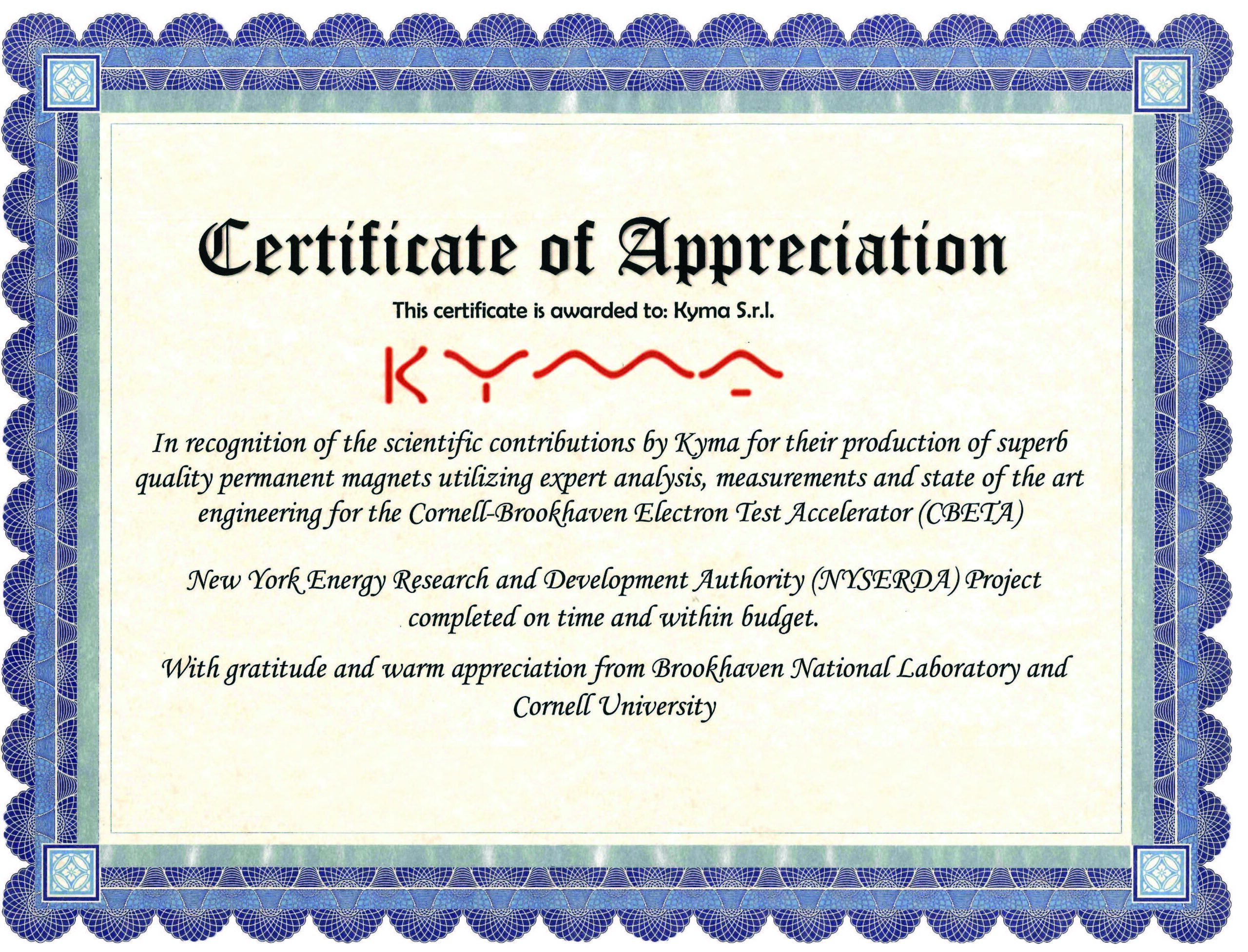

Certificate of Appreciation

Kyma was appointed with the Certificate of Appreciation from Brookhaven National Laboratory and Cornell University for the Cornell-Brookhaven Electron Test Accelerator (CBETA) project

Brookhaven Delivers Innovative Magnets for New Energy-Recovery Accelerator